Cable Schedule | Cable Schedule Format | Cable Schedule Electrical | Junction Box Schedule

Are you struggling to streamline your electrical engineering projects? A Cable Schedule might be the key to enhancing efficiency and organization in your installations. In this comprehensive guide, we’ll delve into the essence of cable scheduling, exploring its significance, techniques, and best practices that can lead to project success. By the end, you’ll be equipped with valuable insights that ensure optimal management of your electrical systems.

What is a Cable Schedule?

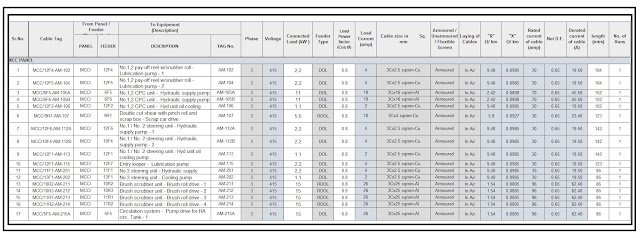

A cable schedule serves as a vital document that details every cable used in an electrical project. It typically includes:

- Cable Type: Such as XLPE or PVC.

- Number of Cores: e.g., 3-core, 4-core.

- Cable Size: Measured in mm² or AWG.

- Length: Total measurement in meters or feet.

- Starting and Termination Points: Where the cable begins and ends.

- Voltage Level: Low, medium, or high voltage.

- Installation Method: Conduits, trenches, or direct burial.

- Cable Route Identification: Clear path for installation.

- Remarks: Fire resistance, waterproofing, etc.

Importance of Cable Scheduling

1. Organization and Efficiency – Provides clarity and reduces errors.

2. Cost Control – Ensures correct procurement and minimizes waste.

3. Safety Compliance – Adheres to NEC/IEC standards.

4. Ease of Maintenance – Simplifies locating cables for modifications.

5. Improved Communication – Enhances collaboration across stakeholders.

Cable Schedule Format

Components of a Cable Schedule

This document is crucial during design and remains useful for installation, commissioning, and future maintenance.

How to Create a Cable Schedule

- Understand the System Layout via Single Line Diagram (SLD).

- Perform cable sizing calculations (capacity, voltage drop, short-circuit ratings).

- Estimate cable lengths including contingencies.

- Assign unique cable IDs (e.g., MCB01-DB02-XLPE).

- Choose installation method based on project needs.

- Record special requirements (fire resistance, waterproofing).

- Compile into a structured table with Excel/AutoCAD.

Best Practices in Cable Scheduling

- Use a standardized format.

- Cross-check with SLDs.

- Update regularly.

- Use software tools (ETAP, AutoCAD).

- Account for environmental factors.

- Plan for future expansion.

Junction Box Schedule

A junction box schedule lists all junction boxes and details such as number, location, size, rating, conductors, and wiring diagrams.

Conclusion

Cable scheduling is crucial for safety, efficiency, and compliance. Following best practices improves project organization, communication, and avoids costly errors.

Frequently Asked Questions (FAQ)

How do I prepare my cable schedule for substation?

Gather equipment/cable details, power requirements, and load demands. Include cable number, type, size, length, termination, and gland info.

What is cable drum schedule?

A cable drum schedule lists drum details (cable type, length, drum size/weight, handling). It helps reduce waste and manage cable cutting.

What is junction box schedule?

A junction box schedule records junction box location, size, number of conductors, type, manufacturer, and wiring diagrams for compliance and maintenance.

What is the purpose of cable layout drawings?

They visually show cable routes and connections, aiding correct installation, troubleshooting, and future upgrades.

How do you calculate cable schedule?

Identify loads and distances, select appropriate cable size/type (capacity + voltage drop), calculate lengths, and record in the schedule.

Post a Comment