VFD | VFD Panel | VFD Panel Drawing | What is VFD Panel | VFD Panel Wiring Diagram | VFD Panel Specifications | What Is an Electric Drive System | AC Drive | VFD Full Form | VFD Full Form in Electrical | AC Motor Speed Control

VFD | VFD Panel | VFD Panel Drawing | What is VFD Panel | VFD Panel Wiring Diagram

- A VFD Variable Frequency Drive (VFD) panel is an electrical panel that houses a VFD, which is a device used to control the speed and torque of an AC electric motor

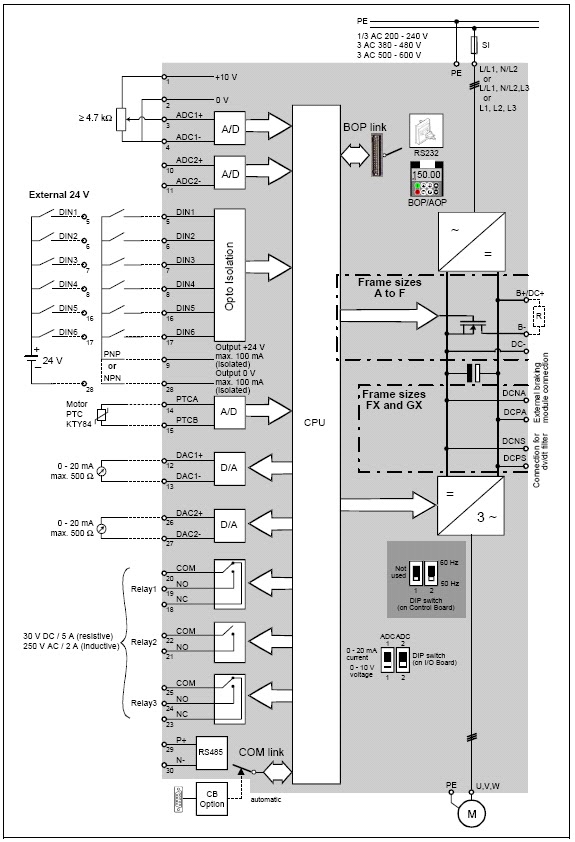

- The VFD panel typically includes a power supply, control circuitry, and a user interface for monitoring and adjusting the motor speed.

- VFD panels are used in a wide range of applications, including HVAC systems, pumps, conveyors, and other industrial equipment.

- The use of a VFD can lead to significant energy savings by allowing the motor to operate at a more efficient speed, reducing the overall power consumption.

- VFD panels can also provide greater control and flexibility in motor operation, allowing for smoother acceleration and deceleration, and more precise speed control.

- The VFD panel must be properly sized and installed to ensure proper operation and maximum efficiency. Factors to consider include the motor's horsepower, voltage, and frequency, as well as the application requirements.

- VFD is AC Drive.

VFD Working Principle Formula | AC Motor Speed Control

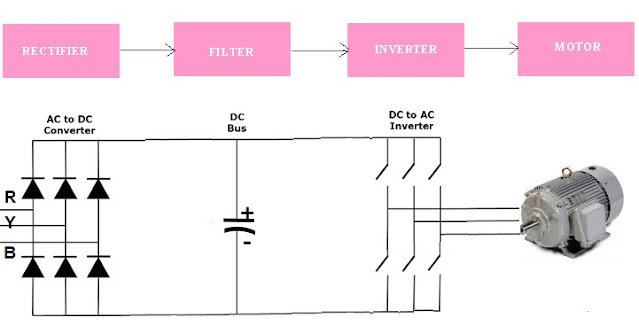

Basically its a motor controller that drives an electric motor by varying the frequency and voltage supplied to the electric motor.

120 X Frequency

N= ----------------------

Motor Poles

VFD are now versatile with high degree of motor control where motor speeds can be accurately varied from zero rpm up to rated RPM.

Also it feature Ramp up (acceleration) and Ramp down (deceleration ) useful especially when higher kW motors are started and stopped.

Whenever R-phase voltage is more positive than Y or B phase voltages, then that diode will conduct and allow current to flow. When Y-phase becomes more positive than R-phase, then the Y-phase diode will conduct and the R-phase diode will off. The same is true for the 3 diodes on the negative side of the bus. Thus, we get six current “pulses” as each diode conducts and off. This is called as Six-pulse VFD, which is the standard configuration for current Variable Frequency Drives.

VFD Control Methods

Scalar or V/F control

In this control system the ratio of Output frequency to the Output voltage is kept constant in order to keep torque constant.

What is Vector Control

Feedback of a motor speed with an encoder is given to drive to calculate a motor slip to identify the load magnitude. This control is a system, which divides the VFD output current into an excitation current (No load current-a current necessary to generate a magnetic flux) and a torque current (a current proportional to the load torque) by vector calculation and controls a frequency and voltage optimally to flow a necessary current individually according to this load magnitude.

Why variable frequency drive is used?

Need of time to conserve energy. For controlling electrical energy consumption and minimizing utility costs it advisable to use variable frequency drive (VFD). Incorporating variable frequency drives into applications such as fans, pumps, and cooling towers can reduce energy use up to 50 percent at partial loads by matching motor speed to the changing load and system requirements.VFD Features:

- Start, stop and variable regulated speed

- Forward/Reverse and toggling between manual and automatic speed adjustment from an external process control signal (e.g close loop system for desired water pressure)

- Alpha-numeric LCD display, indicator lights, and meters to provide text information for communication and maintenance

- A front-mounted or cable-connected keypad for input

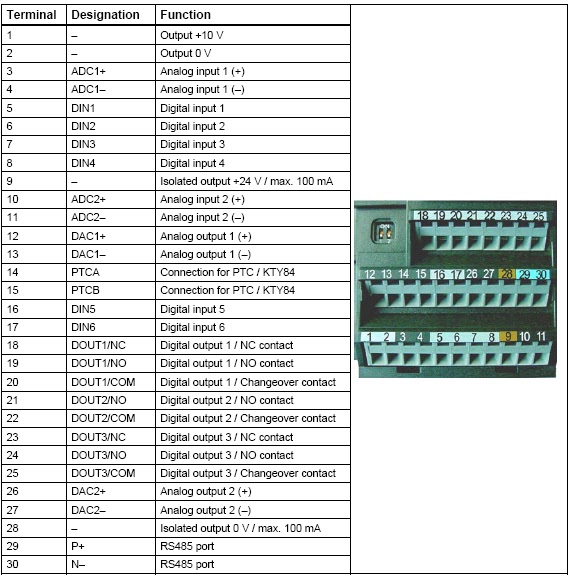

- Input/output terminals available for push buttons, switches and other interface devices

- Serial communication port for variable frequency drive configuring, monitoring and controlling using a computer

- Loading of parameter settings from one VFD to another

Looking for best PLC Training Institute in Delhi NCR ? Come and enrol to avail benefits and learn all types of PLC's like Siemens, Allen Bradley, Delta, Omron, Mitsubishi etc at DIAC Noida. Call @91-9953489987/9711287737 or visit us www.diac.co.in .

ReplyDelete