Soft Starter | Soft Starter Working | Siemens Soft Starter | ABB Soft Starter | Allen Bradley Soft Starter | Soft Starter vs Vfd | What is a Soft Starter| Motor Soft Starter | Soft Starter Working Principle

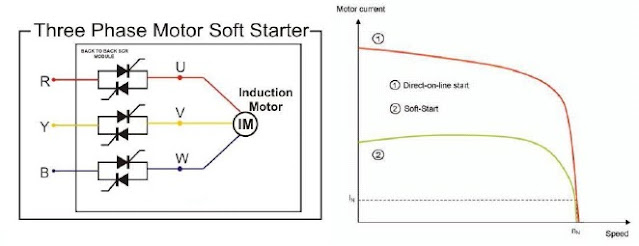

Soft starters are essential components in many industrial applications, providing a cost-effective and efficient way to control the starting and stopping of electric motors. Unlike traditional motor starters, which use direct-on-line (DOL) switching to start the motor, soft starters gradually ramp up the voltage, reducing the inrush current and protecting the motor from damage. This not only extends the lifespan of the motor but also reduces energy consumption and wear and tear on other components in the system. In this article, we will explore the benefits of soft starters, how they work, and some common applications in which they are used.

Soft Starter | Soft Starter Working

- Soft Starters are devices used to reduce the starting current and torque of electrical motors.

- They work by gradually increasing the voltage to the motor, thereby reducing the initial surge of current that can cause damage to the motor or other components in the circuit.

- Soft Starters also help to prolong the lifespan of the motor by reducing wear and tear on the mechanical components.

- These devices are particularly useful for motors that are started frequently or in applications where the starting torque needs to be controlled, such as conveyor systems, pumps, and fans.

- Soft Starters can be configured to provide a range of features, including ramp-up and ramp-down times, current limiters, and overload protection.

- The device monitors the current and voltage of the motor during the starting process, and adjusts the voltage accordingly to ensure a smooth and controlled start.

- Soft Starters are typically easy to install and operate, and can be integrated into existing electrical systems with minimal disruption.

Siemens Soft Starter

The SIRIUS Soft Starter ES engineering tool, which is based on the TIA Portal, makes it easy to parameterize, monitor, and diagnose SIRIUS general and high performance soft starters. We can set device parameters directly on your PC and transfer them to the soft starter via Ethernet cable or a PROFINET connection. With this tool, we can quickly and easily optimize your soft starter's performance, ensuring it operates smoothly and efficiently. Its user-friendly tool is designed to simplify the process of configuring and maintaining SIRIUS soft starters for an engineer or technician

Most commonly used Siemens soft starter series:

Sirius 3RW30: This is a compact and easy-to-use soft starter series that is ideal for controlling standard AC motors. It offers a range of features, including overload protection and flexible parameter settings.

Sirius 3RW40: This series is designed for use with high-performance motors and offers advanced features like torque control and integrated fieldbus communication.

Sirius 3RW44: This series is ideal for use with demanding applications that require precise speed control and high levels of protection. It features built-in motor overload protection and an optional bypass contactor for high reliability.

Sirius 3RW50: This series is designed for use with large motors and provides advanced features like soft stopping and a built-in bypass contactor. It also has a high degree of flexibility in terms of control options.

Sirius 3RW52: This series is similar to the 3RW50, but with additional features like S-bus communication and a power range of up to 630 kW.

ABB Soft Starter

ABB's softstarter is a highly advanced electrical device that provides superior motor protection by effectively minimizing electrical stress on the motor. This not only increases the motor's lifespan but also ensures its smooth operation. The device is equipped with numerous built-in motor protection features, making it a reliable and safe solution for your motor. The user-friendly design of the softstarter makes it simple to learn and set up, ensuring that we can easily optimize the device for your specific application.

ABB's popular soft starter series:

PSR Series: The PSR series is a compact and efficient soft starter designed for various industrial applications. It provides smooth and reliable motor control with a range of features such as built-in bypass contactor, torque control, and underload protection.

PSE Series: The PSE series is a user-friendly and cost-effective soft starter with a built-in bypass. It features an intuitive interface and advanced motor protection features, making it ideal for use in pumps, fans, and conveyors.

PSTX Series: The PSTX series is a versatile and high-performance soft starter that can control motors up to 3000 kW. It has advanced motor control and protection features, such as built-in thermal overload protection, motor current monitoring, and fault detection.

PST Series: The PST series is a reliable and efficient soft starter with a built-in bypass. It features a user-friendly interface and advanced motor protection features, such as overload protection, phase loss protection, and overtemperature protection.

PSS Series: The PSS series is a high-performance soft starter designed for use with medium and large motors. It has advanced control features, such as soft start and soft stop, adjustable starting and stopping torque, and overload protection.

Allen Bradley Soft Starter

Allen Bradley is a popular brand that produces a range of high-quality soft starters for various industrial applications. The Allen Bradley soft starter is an advanced electronic device that is designed to reduce the stress on motors when they are started. By gradually ramping up the voltage, the soft starter is able to minimize the inrush current that can cause damage to the motor, resulting in a longer lifespan for your motor. The device is also equipped with numerous features that ensure the safety and protection of your motor. The Allen Bradley soft starter is easy to set up and use, and is available in a range of sizes and configurations to suit different applications.

SMC-3 Soft Starters: This series is designed for applications that require a small, compact soft starter. It is available in a range of sizes, from 5 to 150 horsepower, and is ideal for simple, standalone applications.

SMC Flex Soft Starters: This series is designed for applications that require more advanced features, such as Ethernet connectivity, diagnostics, and communication capabilities. It is available in a range of sizes, from 5 to 1,500 horsepower, and is ideal for complex applications.

SMC-50 Soft Starters: This series is designed for applications that require a higher level of motor control and protection. It is available in a range of sizes, from 5 to 500 horsepower, and is ideal for applications that require a more advanced level of performance.

Softstarter Bulletin 150: This series is designed for applications that require a highly versatile and flexible soft starter. It is available in a range of sizes, from 5 to 3000 horsepower, and is ideal for demanding applications that require a high level of customization and control.

Induction Motor can be started in following ways:

1. Direct On Line Starting By applying full load voltage at intervals of time

2. Star Delta Starter and Soft starter By applying reduced voltage gradually

3. Auto transformer starter By applying part winding starting

4. Variable Frequency Drive By applying variable voltage & Frequency

Types of Control using Soft Starter:

Soft Starter Working Principle:

Max. Starting Current/ Continuous Current with Soft Starter

|

Motor Rating HP

|

Motor Rating kW

|

Max. Starting Current/ Continuous Current

|

|

1 -6

|

0.75 -4.5

|

20A/6.2A

|

|

7 -10

|

5 -7.5

|

32A/10.5A

|

|

11 -17.5

|

8 -13

|

55A/18A

|

|

18 -35

|

13.5 26

|

110A/36A

|

|

36 -75

|

27 -55

|

150A/75A

|

|

76 -110

|

56 -82

|

230A/115A

|

|

111 -150

|

83 111

|

310A/155A

|

|

151 -197

|

112.5 -147

|

410A/205A

|

|

198 -225

|

147.5 -168

|

470A/235A

|

Nice blog...VFD Drives Suppliers in Chennai

ReplyDeleteSoft Starter Suppliers

SSR Suppliers in Chenna

Push Button Suppliers