Motor Starters | Manual Motor Starters | How Do Motor Starters Work | Star Delta Starter | What is DOL Starter? | Direct Online (DOL) Starter

Motor starters are essential to control the starting and stopping of electric motorsfor. It is an integral part of electrical circuits . There are various types of motor starters available in the market, each designed for different applications and operating conditions. In this guide, we will explore the different types of motor starters, their typical ratings, and component details.

Motor Starters are Essential for | Manual Motor Starters | How Do Motor Starters Work | Star Delta Starter | What is DOL Starter? | Direct Online (DOL) Starter

- A Motor starter is an electrical device used to control the starting current of a motor.

- The starter helps to limit the inrush current that flows through a motor when it is first started, which can prevent damage to the motor and other components in the circuit.

- Motor starters can be manual or automatic and can include features such as overload protection, reversing capability, and variable speed control.

- Manual starters are typically used for smaller motors, while automatic starters are used for larger motors and more complex applications.

- Types of motor starters include direct-on-line (DOL), star-delta, soft starters, and variable frequency drives (VFDs).

- DOL starters provide a full voltage to the motor when it is started, while star-delta starters provide a reduced voltage to limit the starting current.

- Soft starters provide a gradual increase in voltage to the motor to limit the inrush current, while VFDs provide variable frequency and voltage control for precise speed and torque regulation.

- Choosing the right motor starter depends on the motor's size, application, and required features.

Types of Motor Starters

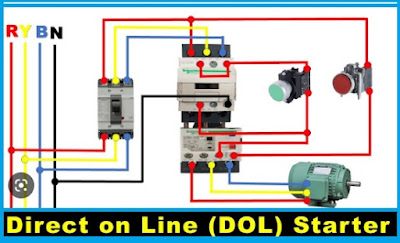

Direct Online (DOL) Starter

DOL starters are the simplest type of motor starters and are suitable for small to medium-sized motors. They provide full voltage to the motor at the start of operation. The typical rating for DOL starters is up to 7.5 kW, and the main components include a contactor, overload relay, and circuit breaker.

Contactor: The contactor is the main component of the DOL starter. It is an electromechanical device that controls the flow of electricity to the motor. The contactor consists of a set of contacts that open and close to control the flow of current to the motor.

Overload Relay: The overload relay is a protective device that is used to protect the motor against overloads. It is connected to the contactor and is designed to trip if the motor draws too much current.

Start Button: The start button is a push-button switch that is used to start the motor. When the button is pressed, it energizes the contactor and allows current to flow to the motor.

Stop Button: The stop button is a push-button switch that is used to stop the motor. When the button is pressed, it de-energizes the contactor and stops the flow of current to the motor.

Auxiliary Contacts: The auxiliary contacts are additional contacts that are connected to the contactor. They are used to control other components in the motor control circuit, such as alarms or indicators.

Star-Delta Starter

Star-delta starters are used for large motors that require reduced starting current. They reduce the voltage to the motor during the starting process and then increase it to full voltage once the motor has reached its normal operating speed. The typical rating for star-delta starters is from 7.5 kW to 75 kW, and the main components include a contactor, overload relay, and timer.

Soft Starter

Soft starters are used for motors that require a controlled start, reducing the starting current and torque. They provide a gradual increase in voltage to the motor, reducing the stress on the motor and extending its life. The typical rating for soft starters is from 7.5 kW to 500 kW, and the main components include a thyristor, control circuit, and bypass contactor.

Variable Frequency Drive (VFD)

VFDs are used for motors that require a variable speed operation. They use a frequency converter to control the motor speed, allowing for energy savings and greater control over the motor operation. The typical rating for VFDs is from 0.5 kW to 500 kW, and the main components include a rectifier, inverter, and control circuit.

Ratings and Component Details

The typical ratings and component details for each type of motor starter are as follows:

1. Direct On-Line (DOL) Starter:

• Rating: up to 7.5 kW

• Components: contactor, overload relay, and circuit breaker

2. Star-Delta Starter:

• Rating: 7.5 kW to 75 kW

• Components: contactor, overload relay, timer, and star-delta switch

3. Soft Starter:

• Rating: 7.5 kW to 500 kW

• Components: thyristor, control circuit, bypass contactor, and current sensors

4. Variable Frequency Drive (VFD):

• Rating: 0.5 kW to 500 kW

• Components: rectifier, inverter, control circuit, and feedback sensors

Conclusion

Motor starters are an essential component in electrical circuits that control the starting and stopping of electric motors. With a wide range of types, ratings, and component details, motor starters can be chosen based on the specific application and operating conditions. By understanding the different types of motor starters and their component details, you can select the right motor starter for your needs and ensure the reliable and safe operation of your motor system.

Post a Comment