PLC | PLC Meaning | PLC Programming | What is a PLC | What is PLC | Allen Bradley PLC | Siemens PLC | PLC Full Form | PLC SCADA

Programmable Logic Controllers (PLCs) are computer-based industrial control systems that are used to automate processes in manufacturing, production, and other industrial settings. They are designed to control a wide variety of processes, including temperature, pressure, flow, and speed, among others. PLCs are widely used in industrial automation and are an essential component of many manufacturing processes.

PLC | What is a PLC? | PLC Meaning | PLC Full Form

Programmable Logic Controller (PLC) is a digital computer that is designed to control various industrial processes. The device is equipped with input and output modules that allow it to interact with sensors and actuators. The input module receives information from sensors, and the output module sends signals to the actuators. The PLC's central processing unit (CPU) then uses this information to make decisions and control the process.

SCADA- Supervisory Data Acquisition

HMI- Human Machine Interface

PLCs are used in a wide range of applications, including manufacturing, food and beverage processing, energy management, and transportation. They are used to control a wide range of processes, including assembly lines, conveyor systems, lighting systems, and HVAC systems, among others.

PLC Programming

PLC programming is the process of writing code that will control the industrial process. The code is written in a programming language that is specific to the PLC manufacturer. The programming language is often based on ladder logic, which is a graphical language that represents the logic of the process as a ladder.

PLC programming is typically done using specialized software that is installed on a personal computer. The software allows the programmer to write, test, and debug the code before downloading it to the PLC. Once the code has been downloaded, the PLC takes over and runs the process.

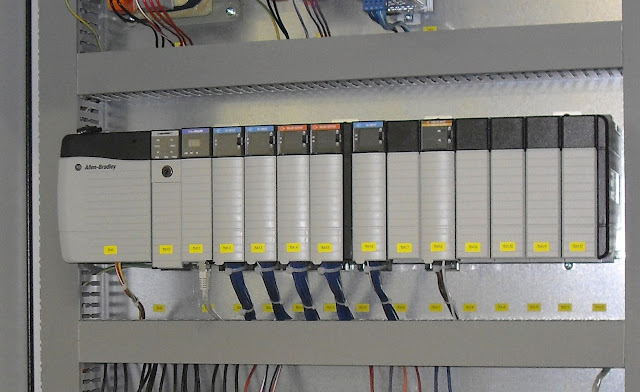

PLC Hardware

PLCs are designed to be rugged and durable, as they are often used in harsh industrial environments. The devices are typically housed in an enclosure that protects them from dust, moisture, and other environmental factors.

PLCs come in a variety of sizes and configurations, depending on the specific application. Some PLCs are designed for small-scale applications, while others are used in large industrial settings. The devices are also available in different levels of complexity, with some offering basic control functions, while others provide advanced programming capabilities.

Types of PLCs

Compact PLCs:

These are small, self-contained PLCs designed for simple applications with a limited number of I/O points.

Modular PLCs:

These are larger PLCs that allow for expansion through the addition of input/output (I/O) modules. They are used in applications that require a greater number of I/O points or more complex programming.

Rack-mounted PLCs:

These are the largest PLCs, and they are designed to be mounted in a standard equipment rack. They allow for the highest number of I/O points and are typically used in large-scale automation applications.

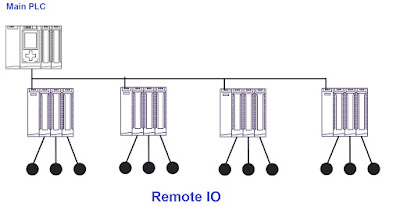

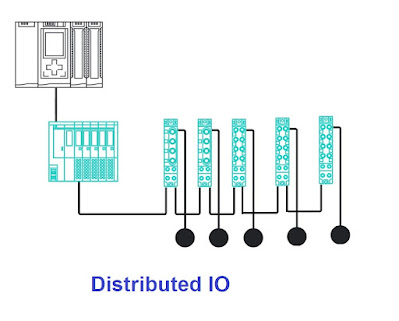

Remote IOs

Remote I/O (Input/Output) is a system used in industrial control applications that allows input/output modules to be located at a distance from the main controller or processor. Remote I/O systems typically use a communication protocol such as Ethernet, Profibus, or Modbus to transmit data between the remote I/O modules and the controller. This allows for flexibility in system design and can reduce the amount of wiring required in the system. Remote I/O systems are often used in applications where the I/O points are spread out over a large area or where it is not feasible to run wires directly to the controller.

Advantages of Remote IOs

Flexibility in system design: Remote I/O systems allow for more flexibility in the design of the control system, as I/O modules can be located at a distance from the controller or processor.

Reduced wiring requirements: Using Remote I/O can reduce the amount of wiring required in the system, which can simplify installation and reduce costs.

Improved system reliability: Remote I/O systems can improve system reliability by reducing the risk of interference or noise on the control signals and by allowing for easier maintenance and troubleshooting of the system.

Scalability: Remote I/O systems can be easily expanded or reconfigured as needed, allowing for greater scalability in the control system.

Remote monitoring and control: Remote I/O systems can allow for remote monitoring and control of the system, which can be useful for systems that are located in remote or hazardous environments.

PLC scan time

PLC scan time refers to the time it takes for a Programmable Logic Controller (PLC) to complete one full scan of its program. A scan is the process by which a PLC reads its inputs, executes its program logic, and updates its outputs.

The scan time is an important parameter in PLC programming, as it affects the responsiveness of the system and its ability to meet the timing requirements of the process being controlled.

The scan time is affected by several factors, including:

Program size: The larger the program, the longer it takes to scan.

Program complexity: Programs with complex logic and a large number of instructions will take longer to scan.

Input/output (I/O) configuration: The number of I/O modules and the type of I/O devices used can affect the scan time.

Processor speed: The faster the processor, the shorter the scan time.

Network communication: If the PLC is communicating with other devices over a network, the network speed and traffic can affect the scan time.

Typically, the scan time of a PLC ranges from a few milliseconds to a few hundred milliseconds, depending on the above factors. In general, it is important to keep the scan time as short as possible to ensure that the system responds quickly to changes in the process being controlled. This can be achieved by optimizing the program logic, minimizing I/O configuration, using faster processors, and ensuring efficient network communication.

PLC Programming Langauges

PLCs can be programmed using several different programming languages, depending on the manufacturer and model of the device. The most common programming languages used in PLC programming include:

Ladder Logic:

Ladder Logic is a graphical programming language that is based on the concept of electrical ladder diagrams. It is the most widely used programming language for PLCs, and it is designed to be easy to read and understand. Ladder Logic is often used for simple applications that require basic control functions.

Function Block Diagram (FBD):

FBD is a graphical programming language that uses functional blocks to represent the logic of the control process. It is similar to Ladder Logic in that it is based on the concept of electrical circuits, but it allows for more complex programming functions.

Structured Text (ST):

Structured Text is a high-level programming language that is similar to traditional computer programming languages. It is designed for more complex applications that require advanced programming capabilities.

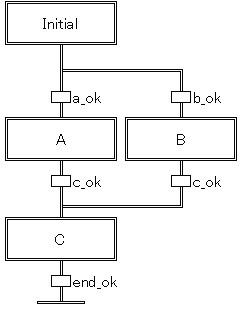

Sequential Function Chart (SFC):

SFC is a graphical programming language that is used to represent complex sequences of events. It is often used for applications that require the coordination of multiple processes.

Instruction List (IL):

IL is a low-level programming language that is used to write PLC programs in a format that is similar to assembly language. It is typically used by experienced programmers who require maximum control over the program execution.

Each programming language has its own strengths and weaknesses, and the choice of language will depend on the specific application and the requirements of the process being controlled. Most modern PLCs support multiple programming languages, which allows programmers to choose the language that best suits their needs.

some examples of each of the programming languages commonly used in PLC programming:

Ladder Logic:

Function Block Diagram (FBD):

Structured Text (ST):

Example: The following structured text code shows how a PID controller can be implemented using ST:

PID_Controller:

VAR

PV : REAL; // Process Variable

SP : REAL; // Set Point

Kp : REAL := 1.0; // Proportional Gain

Ki : REAL := 0.1; // Integral Gain

Kd : REAL := 0.01; // Derivative Gain

e : REAL; // Error

e_prev : REAL := 0.0; // Previous Error

I : REAL := 0.0; // Integral

D : REAL := 0.0; // Derivative

Output : REAL; // Controller Output

END_VAR

// Calculate error

e := SP - PV;

// Calculate Integral

I := I + Ki * e;

// Calculate Derivative

D := Kd * (e - e_prev);

// Calculate Controller Output

Output := Kp * e + I + D;

// Update Previous Error

e_prev := e;

Sequential Function Chart (SFC):

Example: The following SFC diagram shows how a washing machine can be controlled using a sequence of events:

Instruction List (IL):

Example: The following IL code shows how a simple timer can be implemented using IL:

LD I0.0

TOF 100

OUT Q0.0

In this example, the timer is activated when input I0.0 goes high, and it remains active for 100 milliseconds. After the timer has expired, output Q0.0 is set high.

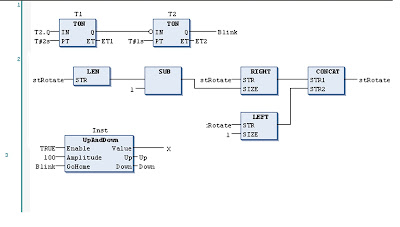

Typical PLC blocks and its function like Set Reset etc

There are several types of PLC blocks or instructions that are commonly used in PLC programming. Some of the most common types of PLC blocks and their functions are:

Set/Reset (S/R) Block: The Set/Reset (S/R) block is used to set or reset a memory bit or flag. The S/R block is often used to create latching circuits in PLC programming.

Timer Blocks: There are several types of timer blocks, including On-Delay Timer (TON), Off-Delay Timer (TOF), and Retentive Timer (RTO). TON blocks are used to delay the turning on of an output, while TOF blocks are used to delay the turning off of an output. RTO blocks are used to maintain a timer value even if the PLC is turned off.

Counter Blocks: Counter blocks are used to count the number of times a particular event has occurred. There are several types of counter blocks, including Up Counter (CTU), Down Counter (CTD), and Up/Down Counter (CTUD).

Comparator Blocks: Comparator blocks are used to compare two values and generate a logical output based on the comparison result. There are several types of comparator blocks, including Equal (EQU), Greater Than (GT), and Less Than (LT).

Math Blocks: Math blocks are used to perform arithmetic operations, such as addition, subtraction, multiplication, and division. There are several types of math blocks, including Add (ADD), Subtract (SUB), Multiply (MUL), and Divide (DIV).

Move Blocks: Move blocks are used to move data from one memory location to another. There are several types of move blocks, including Move (MOV), Move Immediate (MOVP), and Move Block (MOVB).

PLC Advantages

PLCs offer several advantages over traditional control systems. One of the biggest advantages is their flexibility. PLCs can be easily reprogrammed to control different processes, making them ideal for use in manufacturing environments where processes may change frequently.

Another advantage of PLCs is their reliability. PLCs are designed to be rugged and durable, and they are often equipped with redundancy features that ensure reliable operation. Additionally, because PLCs are computer-based, they can perform complex calculations and make decisions quickly, making them ideal for use in high-speed manufacturing environments.

PLCs are also highly scalable, meaning that they can be used in small-scale applications, as well as large industrial settings. They are also relatively easy to install and maintain, which can save time and money in the long run.

Siemens S7-300/S7-400/S7-1200/S7-1500 PLC CPU and IO modules types

Siemens S7-300 PLC:

CPU modules: 312C, 312CPU, 314, 314C, 314CPU, 315-2DP, 315-2AG10-0AB0, 315-2AH14-0AB0, 316-2DP, 316-2AG10-0AB0, 317-2DP, and 317-2AG10-0AB0.

Digital input modules: 321, 321-1BH02-0AA0, 322-1BF01-0AA0, 323-1BL00-0AA0, 324-1BH01-0AA0, and 325-1BP00-0AA0.

Digital output modules: 331, 331-7KF02-0AB0, 332-5HD01-0AB0, 333-5HF00-0AB0, and 334-7KE00-0AB0.

Analog input modules: 331-1KF02-0AB0, 331-7KF02-0AB0, 332-5HD01-0AB0, and 333-1KB00-0AB0.

Analog output modules: 331-1KF02-0AB0, 331-7KF02-0AB0, 332-5HD01-0AB0, and 333-1KB00-0AB0.

Siemens S7-400 PLC:

CPU modules: 412-1, 412-2, 414-3, 414-4H, 416-3, 416-4H, 417-4H, 417-5H, and 417-5HT.

Digital input modules: 6ES7 131-4BB01-0AA0, 6ES7 131-4BF00-0AA0, 6ES7 132-4BF00-0AA0, 6ES7 133-4BB00-0AB0, and 6ES7 134-4GB00-0AB0.

Digital output modules: 6ES7 131-4BD01-0AA0, 6ES7 131-4BF00-0AA0, 6ES7 132-4BF00-0AA0, 6ES7 133-4BB00-0AB0, and 6ES7 134-4GB00-0AB0.

Analog input modules: 6ES7 131-4BF00-0AA0, 6ES7 131-4BD01-0AB0, 6ES7 132-4BD01-0AB0, and 6ES7 133-4BD00-0AB0.

Analog output modules: 6ES7 131-4BF00-0AA0, 6ES7 131-4BD01-0AB0, 6ES7 132-4BD01-0AB0, and 6ES7 133-4BD00-0AB0.

Siemens S7-1200 PLC:

CPU modules: 1211C, 1212C, 1214C, 1215C, and 1217C.

- DI 16x24VDC BA: 6ES7223-1BH32-0XB0

- DI 8x24VDC BA: 6ES7222-1BH32-0XB0

- DI 16x24VDC: 6ES7221-1BF32-0XB0

- DI 32x24VDC: 6ES7222-1HF32-0XB0

- DI 16x24VDC high feature: 6ES7223-1PH32-0XB0

Digital output modules: DO 16x24VDC/0.5A, DO 8x24VDC/2A, and DO 4x24VDC/2A.

Analog input modules: AI 4xU/I/RTD/TC, AI 2xU/I/RTD/TC, and AI 4xU/I/TC.

Analog output modules: AO 4xU/I, AO 2xU/I, and AO 1xU/I.

Siemens S7-1500 PLC:

CPU modules: 1511, 1513, 1515, and 1518.

Digital input modules: DI 16x24VDC, DI 32x24VDC, and DI 16x24VDC high feature.

Digital output modules: DO 16x24VDC/0.5A, DO 32x24VDC/0.5A, and DO 8x24VDC/2A.

Analog input modules: AI 8xU/I/RTD/TC, AI 4xU/I/RTD/TC high feature, and AI 2xU/I/TC high feature.

Analog output modules: AO 4xU/I, AO 2xU/I high feature, and AO 1xU/I high feature.

ABB AC800M/ AC800 / S800/ S100 PEC PLC CPU and type nos

AC 800M PLC:

CPU modules: PM861, PM862, PM864, PM866, and PM891.

Digital input modules: DI801, DI802, DI803, DI804, and DI805.

Digital output modules: DO801, DO802, DO803, DO804, and DO805.

Analog input modules: AI810, AI815, AI820, and AI825.

Analog output modules: AO810, AO815, AO820, and AO825.

AC 800 PLC:

CPU modules: CPU86x, CPU84x, CPU82x, and CPU81x.

Digital input modules: DI81x.

Digital output modules: DO81x.

Analog input modules: AI81x.

Analog output modules: AO81x.

S800 IO system:

Digital input modules: DI801, DI802, DI803, DI804, and DI805.

Digital output modules: DO801, DO802, DO803, DO804, and DO805.

Analog input modules: AI810, AI815, AI820, and AI825.

Analog output modules: AO810, AO815, AO820, and AO825.

Allen Bradley PLC | Rockwell RSlogix PLC type nos and IOs

ControlLogix PLC:

CPU modules: 1756-L6x, 1756-L7x, and 1756-L8x.

Digital input modules: 1756-IA8D, 1756-IA16, 1756-IB16, 1756-IB32, 1756-IB32K, 1756-IC16, and 1756-IF4FXOF2F.

Digital output modules: 1756-OA8D, 1756-OA16, 1756-OB16, 1756-OB32, 1756-OB32K, 1756-OC16, and 1756-OF4FXOF2F.

Analog input modules: 1756-IF8, 1756-IF8I, 1756-IF16, 1756-IF16H, 1756-IF4FXOF2F, and 1756-IF6I.

Analog output modules: 1756-OF8, 1756-OF8H, 1756-OF16, 1756-OF4FXOF2F, and 1756-OF6CI.

CompactLogix PLC:

CPU modules: 1769-L1x, 1769-L2x, 1769-L3x, and 1769-L3xER.

Digital input modules: 1769-IA8I, 1769-IA8V, 1769-IA16, 1769-IB8, 1769-IB16, 1769-IB32, 1769-IC16, and 1769-IF4FXOF2F.

Digital output modules: 1769-OA8I, 1769-OA8V, 1769-OA16, 1769-OB8, 1769-OB16, 1769-OB32, 1769-OC8, 1769-OF4FXOF2F, and 1769-OW8.

Analog input modules: 1769-IF4I, 1769-IF4XOF2, 1769-IF8, 1769-IF8XOF2, 1769-IF16C, and 1769-IF16V.

Analog output modules: 1769-OF2, 1769-OF2VI, 1769-OF4, 1769-OF8C, and 1769-OF8V.

MicroLogix PLC:

CPU modules: 1762-L24BWA, 1762-L24BXB, 1762-L40BWA, and 1762-L40BXB.

Digital input modules: 1762-IQ8, 1762-IQ16, 1762-IQ32, 1762-IA8, 1762-IB8, 1762-IB32, and 1762-IQ8OW6.

Digital output modules: 1762-OW8, 1762-OW16, 1762-OB8, and 1762-OB16.

Analog input modules: 1762-IF2OF2, 1762-IF20F2, and 1762-IF4.

Analog output modules: 1762-OF2 and 1762-OF4.

Schneider Modicon M340 PLC CPU and IO type nos

CPU modules:

- BMXP342020: 20 kB, 1 Ethernet port, 1 USB port, 1 serial port

- BMXP342030: 40 kB, 1 Ethernet port, 1 USB port, 1 serial port

- BMXP342035: 80 kB, 1 Ethernet port, 1 USB port, 1 serial port

- BMXP342036: 160 kB, 1 Ethernet port, 1 USB port, 1 serial port

- BMXP342032: 256 kB, 1 Ethernet port, 1 USB port, 1 serial port

Digital input modules:

- BMXDDI1602: 16 inputs, 24 V DC, sink or source

- BMXDDI1602K: 16 inputs, 24 V DC, sink or source, with removable terminal block

- BMXDDI1602L: 16 inputs, 120 V AC/DC, sink or source

Digital output modules:

- BMXDDO1602: 16 outputs, 24 V DC, sinking or sourcing

- BMXDDO1602K: 16 outputs, 24 V DC, sinking or sourcing, with removable terminal block

- BMXDDO1602L: 16 outputs, 120 V AC/DC, sinking or sourcing

Analog input modules:

- BMXAMI0810: 8 inputs, voltage/current, 0-10 V, +/- 10 V, 0-20 mA, +/- 20 mA

- BMXAMI0812: 8 inputs, voltage/current, 0-5 V, +/- 5 V, 4-20 mA

Analog output modules:

- BMXAMO0210: 2 outputs, voltage/current, 0-10 V, 0-20 mA

- BMXAMO0212: 2 outputs, voltage/current, 0-5 V, 4-20 mA

Communication modules:

- BMXNOE0100: Ethernet communication module

- BMXCPS2000: Serial communication module, RS485

Mitsubishi MELSEC CPU and IO Type Numbers

FX CPU Types

FX1S: This is the most basic FX CPU type, suitable for small-scale applications.

FX1N: This CPU type has a faster processing speed than the FX1S and supports up to 128 I/O points.

FX3U: This is the most advanced FX CPU type, with a high-speed processing capability and support for up to 384 I/O points.

L CPU Types

L02CPU-P: This CPU type is suitable for small-scale applications and supports up to 96 I/O points.

L26CPU-P: This CPU type is designed for mid-range applications and supports up to 256 I/O points.

L36CPU-P: This is the most advanced L CPU type, with a high-speed processing capability and support for up to 512 I/O points.

Q CPU Types

Q02CPU: This is the most basic Q CPU type, suitable for small-scale applications and supports up to 256 I/O points.

Q03UDECPU: This CPU type has a high-speed processing capability and supports up to 384 I/O points.

Q13UDV: This is the most advanced Q CPU type, with a high processing speed and support for up to 1024 I/O points.

iQ-R CPU Types

R08CPU: This CPU type is suitable for small-scale applications and supports up to 384 I/O points.

R16CPU: This CPU type is designed for mid-range applications and supports up to 1024 I/O points.

R12CCPU: This is the most advanced iQ-R CPU type, with a high processing speed and support for up to 4096 I/O points.

Mitsubishi MELSEC PLC Type Numbers:

FX3S-10MR-DS: This is a compact and cost-effective PLC with 10 digital inputs and 6 digital outputs. It has a built-in Ethernet port and can support up to 64 I/O points.

FX3G-40MT/ES: This is a mid-range PLC with 24 digital inputs and 16 digital outputs. It also has 4 analog inputs and 2 analog outputs. It has a built-in Ethernet port and can support up to 256 I/O points.

FX3U-32MT/ES: This is a high-end PLC with 16 digital inputs and 16 digital outputs. It also has 8 analog inputs and 2 analog outputs. It has a built-in Ethernet port and can support up to 384 I/O points.

FX5U-32MT/ES: This is the latest model in the FX series of PLCs. It has 16 digital inputs and 16 digital outputs. It also has 8 analog inputs and 4 analog outputs. It has a built-in Ethernet port and can support up to 384 I/O points.

Mitsubishi MELSEC IO Type Numbers:

FX2N-16EX-ES/UL: This is a digital input module with 16 inputs. It has a 24V DC power supply and a maximum input current of 7mA per point.

FX2N-16EYR-ES/UL: This is a digital output module with 16 outputs. It has a 24V DC power supply and can handle a maximum load current of 2A per point.

FX2N-4AD-PT/ADP: This is an analog input module with 4 inputs. It supports both voltage and current inputs and has a resolution of 12 bits.

FX2N-4DA: This is an analog output module with 4 outputs. It supports both voltage and current outputs and has a resolution of 12 bits.

FX3U-4AD-ADP: This is an analog input module with 4 inputs. It supports both voltage and current inputs and has a resolution of 16 bits.

FX3U-4DA: This is an analog output module with 4 outputs. It supports both voltage and current outputs and has a resolution of 12 bits.

PLC CPU diagnostics information

PLC CPU diagnostics information refers to the data and information that is available to the user for monitoring the status and performance of the CPU in a programmable logic controller. The CPU diagnostics information can help in identifying and troubleshooting issues related to the CPU, such as communication errors, memory errors, or hardware failures.

Common types of CPU diagnostics information that are available in most PLCs:

System Status: This includes information on the status of the CPU, such as power supply, fault status, and running/stopped status.

Communication Status: This includes information on the status of communication between the CPU and other devices on the network.

Memory Status: This includes information on the status of memory usage, such as program memory, data memory, and user memory.

I/O Status: This includes information on the status of the input/output modules connected to the CPU.

Diagnostic Logs: This includes detailed logs of events, alarms, and errors that have occurred on the CPU.

Performance Statistics: This includes information on the performance of the CPU, such as cycle time, scan time, and task execution time.

Hardware Configuration: This includes information on the hardware configuration of the CPU, such as the number and type of input/output modules, communication modules, and other peripherals.

PLC Memory types and typical models for various makes

Program Memory: This is where the PLC program code is stored. It is usually non-volatile memory, meaning it does not require a constant power supply to retain its contents.

Data Memory: This is where the PLC stores input/output data, internal variables, and other program data. It is usually volatile memory, meaning it requires a constant power supply to retain its contents.

EEPROM Memory: This is a type of non-volatile memory that can be used to store data that needs to be retained even when power is removed from the PLC.

Flash Memory: This is a type of non-volatile memory that can be programmed and reprogrammed. It is commonly used for storing firmware updates, configuration data, and other non-volatile data.

Examples of typical PLC models and their memory types:

Siemens S7-300: The S7-300 has a maximum of 2 MB of program memory and 4 MB of data memory. It also has an optional MMC (Multi Media Card) for additional program memory storage.

Allen-Bradley ControlLogix: The ControlLogix has a maximum of 32 MB of program memory and 32 MB of data memory. It also has an optional CompactFlash card for additional program memory storage.

ABB AC800M: The AC800M has a maximum of 32 MB of program memory and 32 MB of data memory. It also has an optional flash memory card for additional program memory storage.

Schneider Modicon M340: The M340 has a maximum of 4 MB of program memory and 4 MB of data memory. It also has an optional SD card for additional program memory storage.

Mitsubishi Q-Series: The Q-Series has a maximum of 32 MB of program memory and 64 KB of data memory. It also has an optional memory card for additional program memory storage.

PLC communication protocols for Siemens, ABB, Rockwell, Schneider, Mitsubishi

Siemens:

- PROFINET

- PROFIBUS DP

- MPI

- AS-Interface

- Modbus TCP/IP

ABB:

- Modbus RTU/TCP

- Ethernet/IP

- Profibus DP

- DeviceNet

- ControlNet

Rockwell:

- Ethernet/IP

- ControlNet

- DeviceNet

- DH+/DH-485

- Modbus TCP/IP

Schneider:

- Modbus RTU/TCP

- Ethernet/IP

- PROFIBUS DP

- DeviceNet

- CANopen

Mitsubishi:

- MELSEC Communication Protocol (MC Protocol)

- Modbus RTU/TCP

- CC-Link

- Ethernet/IP

- Profibus DP

Communication Protocols Overview

PROFINET: A high-speed industrial Ethernet protocol used for real-time control and communication between industrial devices.

PROFIBUS DP: A digital communication protocol used for fieldbus communication in industrial automation, allowing data exchange between devices.

MPI: A proprietary protocol used by Siemens to connect multiple Siemens devices in a network for data exchange.

AS-Interface: A simple and cost-effective communication protocol used for connecting sensors and actuators in industrial automation.

Modbus RTU/TCP: A widely-used communication protocol used for serial communication (RTU) and Ethernet communication (TCP) between devices.

Ethernet/IP: An open communication protocol that uses Ethernet as a physical layer, allowing devices to communicate on an industrial network.

DeviceNet: A communication protocol that connects and controls industrial devices on a network, designed for simple and low-cost connections.

ControlNet: A deterministic communication protocol used for real-time control and high-speed data exchange between devices.

DH+/DH-485: A communication protocol used by Rockwell Automation for connecting and controlling devices in a network.

CC-Link: A high-speed communication protocol used in industrial automation for connecting and controlling devices in a network.

MELSEC Communication Protocol (MC Protocol): A proprietary protocol used by Mitsubishi Electric for communication between Mitsubishi PLCs and other devices.

CANopen: A standardized communication protocol used for industrial automation, allowing devices to communicate with each other and exchange data.

PLC Maintenance & troubleshooting tips

Regular maintenance: Regularly check for worn-out components, damaged cables or wires, and ensure proper grounding and shielding of your equipment.

Backup your programs: Always keep a backup of your PLC programs and parameters to avoid loss of data in case of equipment failure.

Keep software updated: Keep your PLC software up to date with the latest versions and updates provided by the manufacturer.

Monitor system performance: Monitor system performance regularly and keep track of any abnormalities or errors in the system.

Use diagnostic tools: Use diagnostic tools and software provided by the manufacturer to identify issues and diagnose problems in the system.

Conduct regular inspections: Conduct regular inspections of your system to ensure proper wiring, mounting, and installation of your equipment.

Proper training: Provide proper training to your maintenance and operations team to ensure they are familiar with the system and can troubleshoot common issues.

Analyze system logs: Analyze the system logs and error codes to identify recurring issues and take preventive measures to avoid them in the future.

Address issues immediately: Address any issues as soon as they arise to avoid further damage or downtime.

Consult manufacturer documentation: Consult the manufacturer's documentation and manuals for troubleshooting guidelines and instructions on maintenance and repairs.

Sink and Source voltage in PLC

In PLCs, the terms "sink" and "source" refer to the way in which the input/output (I/O) signals are connected to the PLC.

A "sinking" input/output means that the signal is connected to ground (0V) through the input/output module, while a "sourcing" input/output means that the signal is connected to the positive voltage supply (+V) through the input/output module.

The voltage levels for sinking and sourcing inputs/outputs vary depending on the PLC manufacturer and model, but typically range from 5-24VDC.

For example, in a 24VDC system, a sinking input signal would be connected to ground (0V) and the input module would sense the voltage drop across the input resistor. In contrast, a sourcing input signal would be connected to the positive voltage supply (+24V) and the input module would sense the voltage across the input resistor.

It is important to ensure that the input/output module used is compatible with the type of signal used in the system, whether it is sinking or sourcing, to prevent damage to the PLC or the connected devices.

PLC Vs DCS

PLC (Programmable Logic Controller) and DCS (Distributed Control System) are two types of industrial control systems that are used for controlling and monitoring processes in industries.

PLCs are designed for discrete control applications, where a small number of I/O points are required and the process can be broken down into simple steps. PLCs are ideal for controlling discrete processes such as assembly lines, packaging systems, and material handling equipment.

DCS, on the other hand, is designed for process control applications where a large number of I/O points are required, and the process is continuous and complex. DCS is ideal for controlling processes such as power generation, chemical processing, and oil refineries.

The main differences between PLCs and DCSs are in their architecture, functionality, and scalability. DCSs typically have a distributed architecture, where the control functions are distributed among multiple controllers, while PLCs have a centralized architecture, where all control functions are performed by a single controller.

DCSs provide advanced control functions such as regulatory control, advanced process control, and batch control, which are not available in PLCs. DCSs also have the capability to integrate with other systems such as MES (Manufacturing Execution Systems) and ERP (Enterprise Resource Planning) systems, which allows for real-time data exchange and decision making.

In summary, PLCs are suitable for discrete control applications, while DCSs are better suited for process control applications that require advanced control functions and scalability.

Safety PLC

A Safety PLC is a specialized type of programmable logic controller (PLC) that is designed to meet safety standards and requirements for safety-critical applications. Safety PLCs are used in industries such as automotive, food and beverage, oil and gas, and pharmaceuticals, where safety is of utmost importance.

Safety PLCs are designed to monitor safety devices, such as safety switches and light curtains, and to take appropriate actions if any safety-related issues are detected. They typically have built-in safety functions, such as emergency stop, safety gates, and safety interlocks, and they are programmed using safety programming languages such as Function Block Diagrams (FBD) and Sequential Function Charts (SFC).

Safety PLCs are required to meet stringent safety standards, such as the IEC 61508 and the ISO 13849, and they are certified by independent certification bodies to ensure that they meet these standards. Safety PLCs typically have redundant hardware and software to ensure high levels of safety and reliability.

Typical Safety PLC makes and models

Allen-Bradley GuardLogix Safety Controllers

Siemens Simatic Safety Integrated

ABB AC500-S Safety PLCs

Schneider Electric Modicon M580 Safety Controllers

Omron NX-series Safety Controllers

Rockwell Automation Compact GuardLogix 5380 Safety Controllers

Mitsubishi MELSEC Safety PLCs

These Safety PLCs are designed to meet different safety standards and requirements and can be used in a variety of safety-critical applications in industries such as automotive, food and beverage, pharmaceuticals, and oil and gas.

PLC Installation and commissioning guidelines

Installing and commissioning a PLC system requires careful planning and execution to ensure a successful implementation. Here are some general guidelines to follow:

Prepare the installation site: Ensure that the installation site is clean, dry, and free from dust, dirt, and debris. Install the PLC in a location that is easily accessible for maintenance and repair.

Check the power supply: Ensure that the power supply is stable and has the correct voltage and current rating for the PLC system.

Install the hardware: Install the PLC hardware components, such as the CPU module, IO modules, power supply, and communication modules, according to the manufacturer's instructions.

Connect the IO devices: Connect the IO devices, such as sensors, switches, and actuators, to the IO modules according to the wiring diagram and manufacturer's instructions.

Configure the PLC: Configure the PLC system using the programming software and set the parameters for each IO device.

Test the system: Perform a thorough functional test of the system to ensure that all components are functioning correctly and that the system meets the desired specifications.

Train the operators: Provide training to the operators on how to use the system and respond to any potential faults or alarms.

Document the installation: Create a detailed installation and commissioning report that includes the system configuration, test results, and any relevant information for future reference.

Conclusion

In conclusion, PLCs are a critical component of industrial automation, and they are used in a wide variety of applications. They offer several advantages over traditional control systems, including flexibility, reliability, and scalability. PLC programming is a specialized skill that requires knowledge of specific programming languages and software. With their advanced capabilities and rugged design, PLCs are an essential tool for modern manufacturing and industrial processes.

Frequently Asked Questions-FAQ

Q: What is a PLC meaning?

A: A PLC or Programmable Logic Controller is a digital computer used for industrial automation and control of machinery or production processes.

Q: What are the 3 types of PLC?

A: The three types of PLCs are compact PLCs, modular PLCs, and rack-mounted PLCs.

Q: What is PLC and how it works?

A: A PLC is a programmable digital computer used for industrial control applications. It works by taking inputs from various sensors and switches, processing the data through a program or logic, and then providing outputs to control various devices such as motors, valves, and actuators.

Q: What is PLC and SCADA?

A: PLC and SCADA are two types of industrial control systems used for controlling and monitoring processes in industries. PLCs are used for controlling discrete processes, while SCADA is used for monitoring and controlling large and complex processes.

Q: What is a SCADA device?

A: A SCADA (Supervisory Control and Data Acquisition) device is a computer system used for monitoring and controlling industrial processes. It is used to gather real-time data from various sensors and devices, and to control the processes remotely.

Q: What is SCADA basic function?

A: The basic function of a SCADA system is to gather real-time data from various sensors and devices, process the data, and provide control signals to remote devices for controlling and monitoring industrial processes. It also provides a user interface for operators to monitor the processes and make necessary changes to optimize performance.

Post a Comment